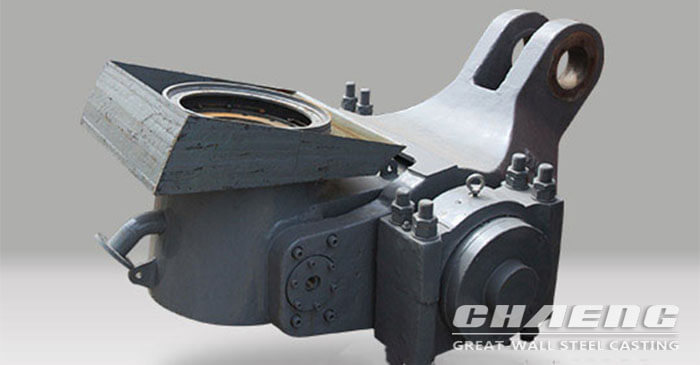

Vertical Mill Rocker

Weight :10-25 t

MaterialASTM :1035 / DIN: CK35

Applicable devices: vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills.

Application: Cement, building material, chemical, coal, electricity, metallurgy and non-metallic mine

Customizable: Yes

Vertical mill rocker is one of key components of vertical grinding mill. It includes upper rocker, down rocker, rocker shaft, bearing, bearing seat, etc. The upper rocker is used to install the grinding roller, and the down rocker connects with hydraulic system. Two rockers are connected into a whole by shaft, taper sleeve and taper pin.

Advantages:

1.The vertical mill rocker produced by Great Wall Steel Casting has better wear-resistant capability and good anti-cracking.

2.We carry out the dressing and finishing by arc air gouging and shot-blasting for the steel castings to guarantee the appearance quality.

3.Before delivery, all the rockers will have NDT inspection several times as per perfect inspection flow. Any defective product is forbidden to leave factory.

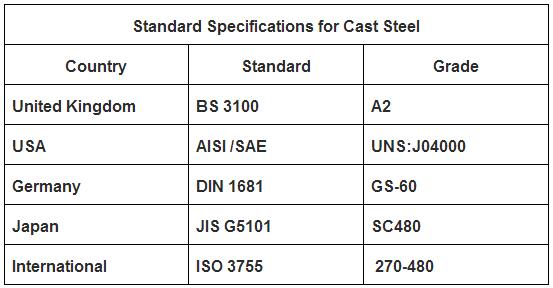

Our main material for vertical mill rocker arm is similar as followings:

Quality Assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Our service:

- Prompt response in 24h after your inquiry

- Several years high-precision processing experience

OEM service

- Advanced management ability with high technology

- Strictly quality control

- We can design the production drawing when you supply the design drawing.

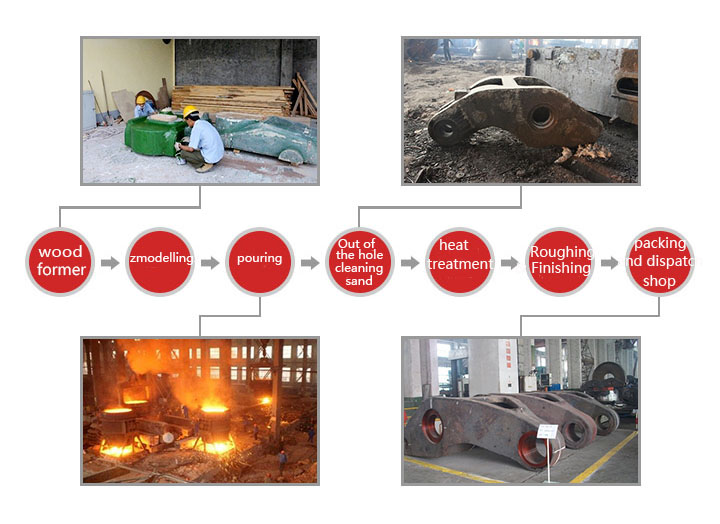

Vertical Mill Rocker Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

There are many customers in China. The steel casting products can meet both requirements of domestic production process, and international advanced production standards. It have won a good reputation from new and regular customers especially in Tianjin, Henan, Hebei, Dalian, Tangshan etc. because of its good post operation. The casting products ensure the vertical mill’s effective operation.

Application:

- cement vertical roller mill

- coal vertical roller mill

- raw vertical roller mill

- slag vertical roller mill