Grinding Table

Weight : 20-132 t

Material : ASTM: A570 / BS: S235JR

Applicable device: Vertical roller mill

Application: Cement, building material, chemical, coal, electricity, metallurgy, non metallic mine and others

Customizable: Yes

Grinding table is one of key parts of vertical roller mill. It includes drag rings, lining plate and base. The optimization and improvement are made basing on traditional grinding table casting technology, that the most advanced sodium silicate-bonded sand molding technology, to overcome deficiencies in structure and make the grinding base bear force equivalently. All these measures avoid material’s washout problem on no-wear-resisting surface.

Advantage of grinding table:

1. High hardness, anti-cracking, wear resistant, fine workmanship

2. Arc air gouging and shot blasting are used to casting steels’ finishing, to make sure good appearance quality.

3. NDE inspections are applied on stress surface before delivery, to ensure products are good in stress capability and stable in operation.

Quality assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Our service:

Prompt response in 24h after your inquiry

Several years high-precision processing experience

OEM service

Advanced management ability with high technology

Strictly quality control

We can design the production drawing when you supply the design drawing.

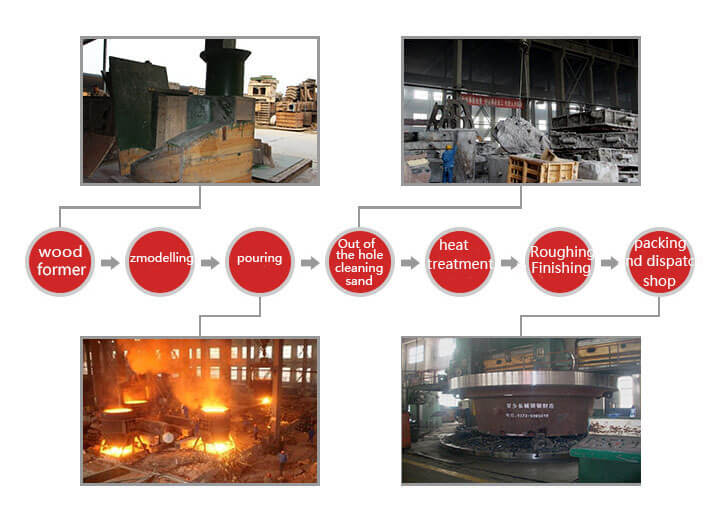

Grinding Table Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case :

Through many years’ efforts and development, Great Wall Steel Casting’s customers are all over China and Europe, America, Germany and other countries. The good service and product quality makes Great Wall Steel Casting a strategic partner with world famous large machinery manufacturers, Xinxiang Great Wall Machinery, etc.

Application:

- cement vertical roller mill

- coal vertical roller mill

- raw vertical roller mill

- slag vertical roller mill