Grinding roller

Weight : 20-120 t

Material:ASTM : 1030 / DIN: 30Mn4

Applicable devices: vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills.

Application: Cement, building material, chemical, coal and others

Customizable : Yes

Grinding roller is core part of vertical mill. Great Wall Steel Casting can provide customized service according to customers’ different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc. We gained good reputation from customers.

Advantages:

1. Grinding rollers produced by Great Wall Steel Casting have features of high hardness, good anti-cracking and strong wear-resistant capability.

2. During grinding roller production, technicians carry out finishing processing with arc air gouging, which can guarantee outlook quality of steel castings.

3. We promise that, all the grinding rollers shall be NDT inspected on the stress surface through routing testing methods to ensure that each grinding roller is qualified before leaving our factory. Any sub-standard product is forbidden to leave factory.

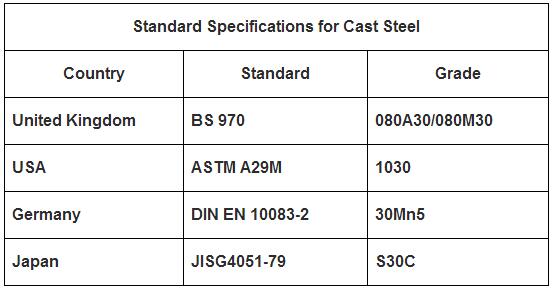

Our main material for the Grinding roller for vertical mill is similar to followings:

Quality assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Our service:

- Prompt response in 24h after your inquiry

- Several years high-precision processing experience

OEM service:

- Advanced management ability with high technology

- Strictly quality control

- We design the production according to your drawing when you supply the design drawing.

Grinding Roller Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

Great Wall Steel Casting supplies grinding roller for international well-known vertical mill manufacturer. The good quality and perfect service gained trust from For Foreign Company. Therefore, Xinxiang Great Wall Steel Casting becomes its best supplier.

Grinding rollers of Great Wall Steel Casting were applied to the cement vertical mill with annual output 900,000 tons of Henan Yuhui Huanghe Building Material Co., Ltd.

Application:

- cement vertical roller mill

- coal vertical roller mill

- raw vertical roller mill

- slag vertical roller mill