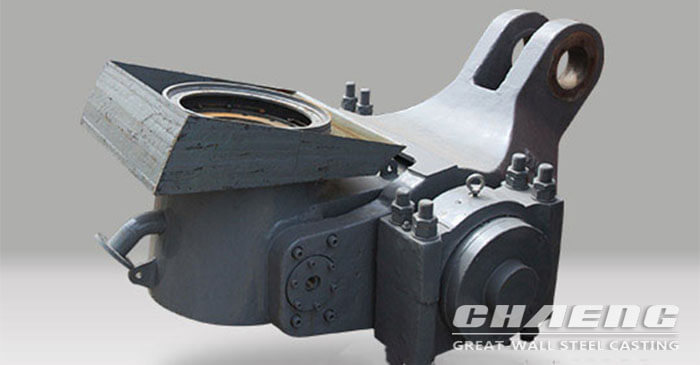

Ball mill hollow shaft

Weight : 5-30 t

Material : ASTM: 1025 / DIN: CK25

Applicable device: Ball Mill,Tube Mill,rod mill

Application: Cement, metallurgy, building material and others

Customizable : Yes, according to your drawings

Customized ball mill spare parts: ball mill trunnion (hollow shaft), ball mill head

Great Wall Steel Casting customizes large spare parts of ball mill according to customers' drawings: ball mill hollow shaft (ball mill trunnion), ball mill trunnion bearing, ball mill end cover, ball mill gear ring, and so on.

Ball mill hollow shaft (trunnion) is an important part to load the mill rotary body. it has strict requirement for casting technology. Great Wall Steel Casting is one of the largest casting enterprises in CHINA that are capable of producing high quality ball mill trunnion.

Advantages:

1. CHAENG uses special heat treatment technology to improve the hardness and enhance impact resistance of the ball mill.

2. Uses high strength steel material.

3. Optimized the technical structure of ball mill trunnion according to running characteristics of ball mill, to guarantee the stability of the trunnion during long time running, but and prolong its working life.

4. Great Wall Steel Casting has strong casting capability, and it can provide casting parts with good quality and short production period.

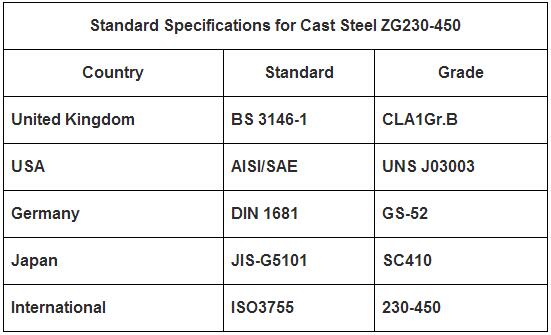

Our main material for the ball mill hollow shaft is similar to the followings:

Mill Hollow Shaft Process Measures:

- Molten steel secondary refining (R-H vacuum treatment)

- Modeling using special sand, strictly control the pouring temperature and casting speed

- Journal processing to ensure concentricity and roughness of the end surface of the mouth

Mill Hollow Shaft Quality Tests :

- Rough casting mechanical properties and chemical composition(internal standard)

- Ultrasonic testing after rough machining

- Ultrasonic testing and magnetic particle testing after finishing

Ball Mill Trunnion Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

The ball mill produced by Great Wall Machinery exported to Russia, the USA, India and other countries, trunnions as the main casting of ball mill are produced by our factory.

Application:

- Cement Ball Mill

- Coal Ball Mill

- Slag Ball MIll

- Raw Ball Mill

- Mine Ball Mill