Girth Gear

Weight: 10~35T

Diameter: 2m-14m

Material: Cast steel

Applicable devices: Rotary kiln, ball mill

Application: Cement, building material, metallurgy etc.

Customizable or not: Yes, according to your drawings

Girth gear, also called gear ring or gear wheel is large diameter internal ring gears for heavy duty equipment. Great Wall Steel Casting provides customised girth gear for ball mill and rotary kiln according to customers' drawings.

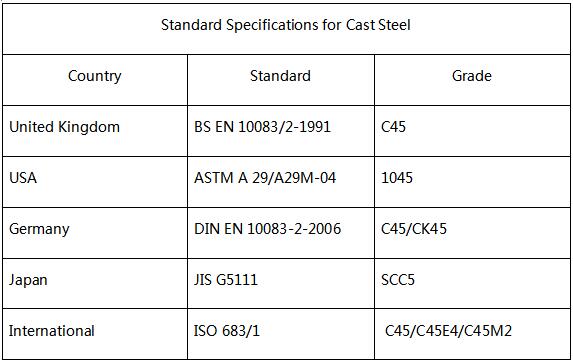

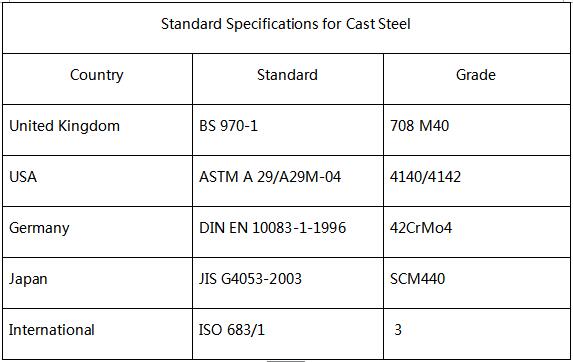

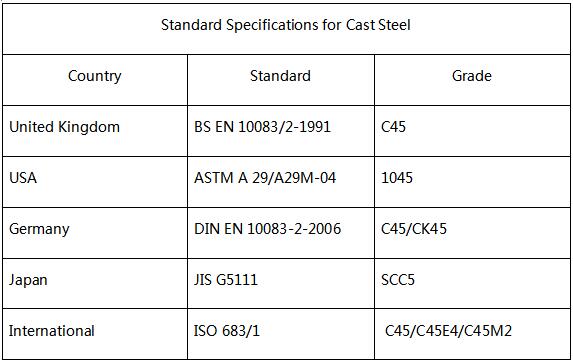

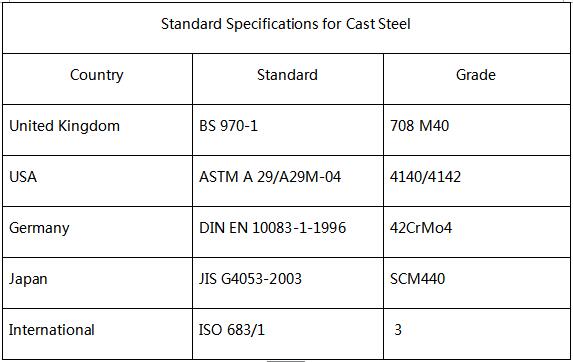

Our main material for the Girth Gear is similar to followings:

Advantages of CHAENG girth gear:

1. Adopt special heat treatment technology to improve the structure optimization, the hardness, and enhance the wear-resistant and anti-impacting performances.

2. Adopts high strength steel materials.

3. Optimize girth gear based on the operation characteristics of the rotary kiln and ball mill, to ensure the stability of the girth gear during the long time operation and extend its service life.

4. Great Wall Steel Casting has large production capability in steel castings, so we can provide girth gear with short cast period and large amount.

CHAENG Girth Gear (Rotary Kiln or Ball Mill) Quality Testing:

1. Girth gear rim is casted in two halves

2. Nondestructive testing is performed to ensure zero defects

3. Machining of gear in multiple steps to ensure best finish and accuracy

4. Final quality inspection to ensure CPG quality

Girth Gear Quality assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a "s-built" sketch;

• Record of the heat treatment chart;

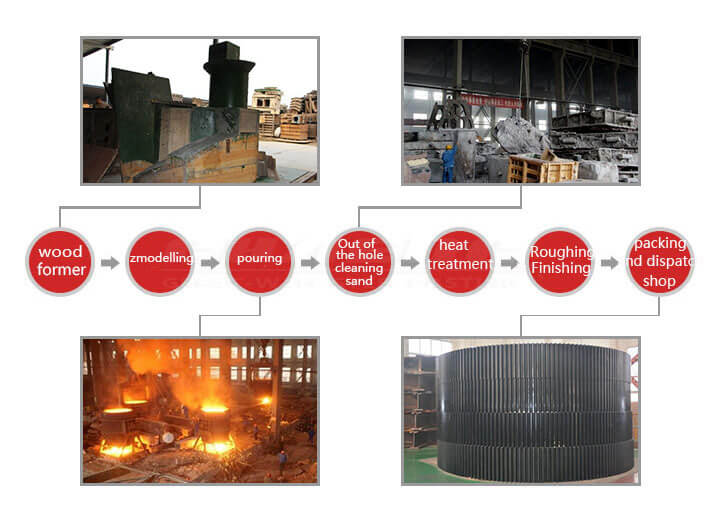

Gear Ring Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Cases:

Great Wall Steel Casting’s girth gears are applied in rotary kiln and ball mill for Turkey Tracim cement company,besides,we have many other cases as follows:

- Xinjiang Tianshan Building Material Group ordering 23t girth gear for rotary kiln.

- Henan Mengdian Group ordering 15t girth gear for cement ball mill.

Application

- cement ball mill

- coal ball mill

- slag ball mill

- cement rotary kiln

- lime rotary kiln