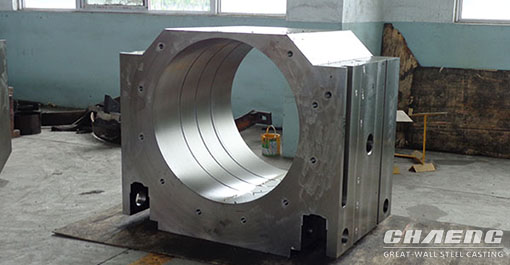

Roller Shaft Bearing chock

Weight : 3~10 t

Material : ASTM: A-27 70-40 / JIS: SCW480

Applicable devices: coal ball mill part

Application: cement, electricity, .metallurgy, chemical industry, non-metal mine etc.

Customizable : Yes

The roller shaft bearing chock is the major component of coal mill. The roller shaft bearing are well sold in domestic market and exported to Japan, Russia and other countries, and gained good reputation from our customers. Currently, many customers who use our roller shaft bearing express that the roller shaft bearings produced by Great Wall Steel Casting have stable quality and good performance.

Advantages:

1. The particular heat treatment technology is used in the process of production, which greatly improves its hardness.

2. The roller shaft bearing chock is casting with high strength steel, which ensures the stability of the casting under long time operation and extends its service life.

3. The company has strong production capability in steel castings. It can provide castings like roller shaft bearing chock in large quantity with short delivery time.

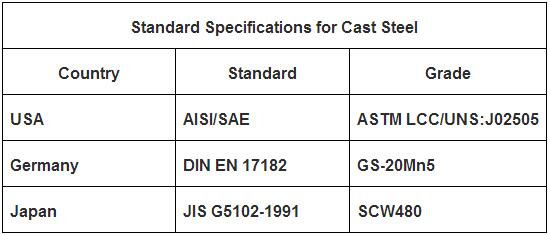

Our main material for the Rolling shaft bearing is similar to followings:

Quality assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Our service:

- Prompt response in 24h after your inquiry

- Several years high-precision processing experience

OEM service:

- Advanced management ability with high technology

- Strictly quality control

- We design the production according to your drawing when you supply the design drawing.

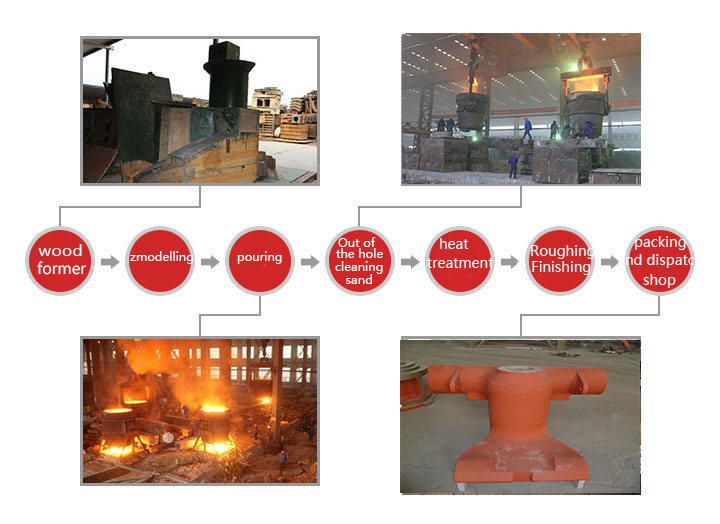

Bearing Chock Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

Xinxiang Great Wall Machinery and many other famous coal mill manufacturers use the roller shaft bearing chocks produced by us. They are satisfied with the quality, delivery time and our service.

The coal mill produced by Xinxiang Great Wall Machinery which exported to Japan is equipped with the roller shaft bearing chock and other steel castings produced by us. It has been proved that the steel castings are in high quality and cost-effective.