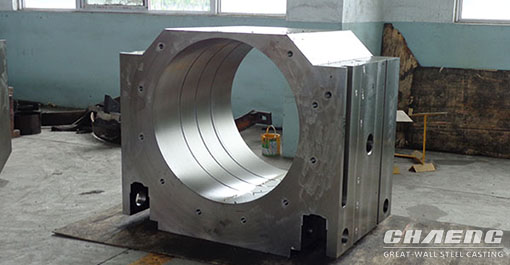

Bearing Chock

Weight : 1-150t

Material : ASTM: A-27 70-40 / DIN: 20Mn5

Applicable device: coal mill parts

Application: Cement, electricity, metallurgy, chemical and others

Customizable : Yes

The bearing chock is an important component to fixed bearing. It is the core unit for the weight-supporting and rolling bearing. It acts as a support in the bearing component. Bearing chock works continuously under the circumstance of low speed and heavy duty, along with the impact. So it is important to have a good quality guarantee for the components.

Advantages:

1. Good material and high degree of wear resistance.

The bearing chock is made from SCW480 material guarantee the quality of the finished product. The bearing seat can still keep stable and effective and less loss in high-load and long time operating through the practice of inspection.

2. Complete monitoring equipment available to current operation state.

The bearing seat is equipped with observation oil level. The operators can see the oil level height and timely supply oil. So it can prevent lead to bad lubrication for lack of oil and avoid the bearing damage accidents.

3. Reasonable structure, conductive to long-term stable operation.

Take out the bearing outer roof and prevent dust from entering the bearing box. So ensure the service life and safe and reliable operation of the bearing.

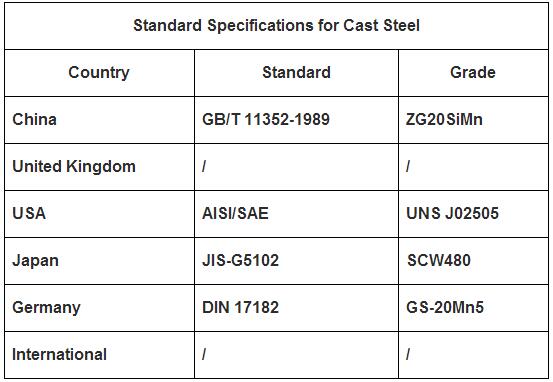

Our main material for the rolling mill chocks is similar as following:

Quality assurance:

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart;

Our service:

- Prompt response in 24h after your inquiry

- Several years high-precision processing experience

OEM service:

- Advanced management ability with high technology

- Strictly quality control

- We design the production according to your drawing when you supply the design drawing.

Bearing Chock Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

Henan Zhongyuan Heavy Forging Company ordering our 68t bearing chock for rolling mill.

Application:

- Rolling Mill

- Coal Mill Accessories