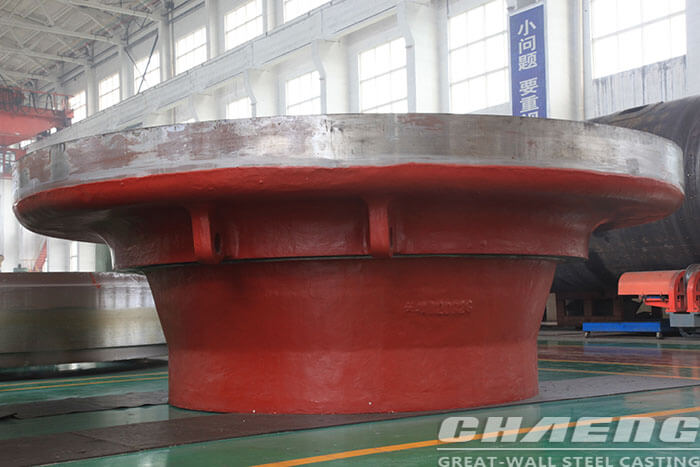

Grinding table in vertical cement mill

16 May 2018 UTC+8Views:

The grinding table is one of the key parts of vertical roller mill. It is mainly composed of a resistance ring, a liner and a base. CHAENG optimizes the design of grinding table process and adopts high-quality carbon steel and silicon-manganese steel materials to produce the grinding table which is much favored by customers with stronger wear resistance and longer service life.

CHAENG can customize grinding table according to the drawings provided by the customers in strict accordance with the series of casting procedures, carefully controlling each step. The running data of CHAENG grinding tables in each major cement production line is stable, which proves the absolute advantages as follows:

1. Optimize the casting technology of grinding table and adopt advanced water glass sand modeling process to overcome the shortcomings of the previous structure, so that the grinding table base bears stress evenly; Increase the nip angle between grinding table and grinding rollers to avoid the erosion of the non wearing surface of grinding table;

2. Advanced machining equipment to ensure high surface finish of grinding table;

3. Nondestructive inspection of the stress surface before leaving the factory can ensure that the internal and external quality of the grinding table conforms to the industry standards;

4. CHAENG has a large steel casting base in the northern area of Henan Province, so it can not only provide a single grinding table manufacture service, but also provide solutions of large steel casting product for you!

If there is serious wear on the vertical mill grinding table of your production line and you need to replace the new grinding table, welcome to visit CHAENG. The excellent quality and perfect service will surpass your expectations!

E-mail: casting@chaeng.co

Tel.:86-371-55019878

Skype ID: greatwall1958