specification

Weight1-300 Tons

MaterialSteel ZG45, ZG42CrMo

ApplicationRotary kiln, rotary dryer, etc

CustomizableYes, according to the drawings or dimensions from customers

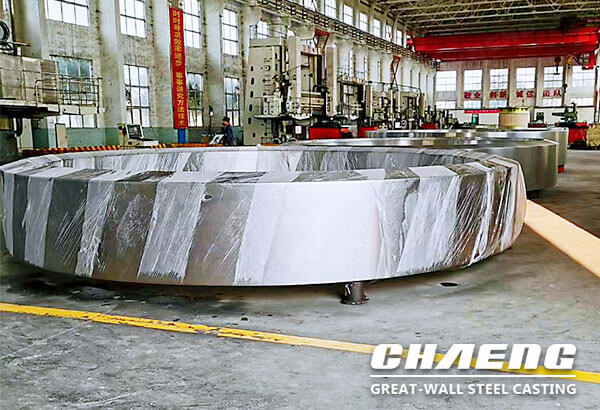

The rotary kiln tyre, also known as the riding ring, is one of the main components of the rotary kiln. It is to transfer all the gravity of the kiln body to the supporting roller, and it is also a part that strengthens the radial rigidity of the cylinder. Therefore, the kiln tyre should have sufficient strength and durability.

CHAENG uses high-quality cast steel materials and strictly controls the quality of each production step, to ensure that the rotary kiln tyres have sufficient strength, durability, and rigidity.

Weight1-300 Tons

MaterialSteel ZG45, ZG42CrMo

ApplicationRotary kiln, rotary dryer, etc

CustomizableYes, according to the drawings or dimensions from customers

1. CAE software digital simulation technology is used to assist in quality prediction and process optimization.

2. The CHAENG kiln tyres has been treated by double-medium quenching process, which has the characteristics of high quenching hardness and high toughness, so that the kiln tyre has good wear resistance and can adapt to various harsh working environments.

3. Strictly control raw material sample testing, product inspection, quality assessment, etc.

4. A scientific production management system to ensure the product quality and delivery time.

5. Our company has complete quality inspection system to ensure the quality of steel castings: chemical composition, mechanical property, dimensional check, ultrasonic testing (UT), magnetic particle testing (MT), penetrant test (PT), X-ray inspection, etc.

Simulation & analysis

Wood pattern

Sand mould

Smelting

Molten steel test

Pouring

Sand cleaning

Heat treatment

Finishing

Machining

Non-destructive testing

Packaging & delivery

Excellent product quality makes CHAENG rotary kiln tyre sold to Henan, Guangxi, Zhejiang and other provinces, and also to many well-known overseas enterprises in Indonesia, the Philippines, Italy, Turkey, Chicago, Kazakhstan, United Arab Emirates, and others.