specification

Weight> 1 Ton

MaterialCast steel ZG230-450

ApplicationCement, metallurgy, building materials and other industries

CustomizableYes, as customer's drawings

The ball mill trunnion is the key component to support and connect the cylinder, and it is the passage of material in and out. The journal bears mainly the bending force during operation. The trunnion neck that is in contact with the spherical bush of the ball mill and the arc neck that is in connection with the cylinder must not have casting defects of pores and sand holes. And the part that is in contact with the spherical bush needs to be ground to ensure accuracy and smoothness.

CHAENG adopts high-strength steel and unique heat treatment technology, so that the ball mill trunnion has high hardness and strong impact resistance, which can greatly ensure the long-term stable operation of the trunnion.

Weight> 1 Ton

MaterialCast steel ZG230-450

ApplicationCement, metallurgy, building materials and other industries

CustomizableYes, as customer's drawings

1. The unique heat treatment process improves the hardness and impact resistance of the ball mill trunnion.

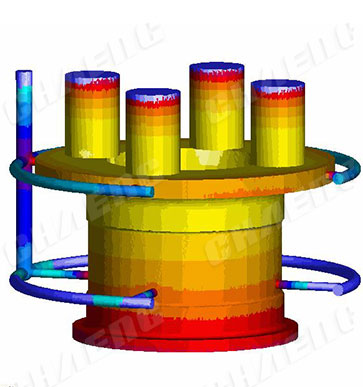

2. Use digital simulation technology to improve the casting process.

3. We strictly control the quality and ensure there are no casting defects such as gas holes and sand holes in the trunnion journal.

4. Shot blasting equipment is used to improve the surface quality of ball mill trunnion.

5. Complete quality inspection methods: chemical composition, mechanical property, dimensional check, ultrasonic testing (UT), magnetic particle testing (MT), penetrant test (PT), and X-ray inspection.

6. Scientific production and operation management system to ensure the delivery time.

Simulation & analysis

Wood pattern

Sand mould

Smelting

Molten steel test

Pouring

Sand cleaning

Heat treatment

Finishing

Machining

Non-destructive testing

Packaging & delivery

A well-known cement manufacturer in China purchased a φ4.2×13m cement mill from Xinxiang Great Wall Machinery Co., Ltd. The core component—ball mill trunnion—was supplied by Great Wall Casting.

Xinxiang Great Wall Machinery's ball mills are sold to many areas and countries, and the ball mill trunnions are all independently manufactured by us.

Panamanian customers purchased a batch of ball mill trunnions