Building Materials Industry

Metallurgical Industry

Mining Industry

Forging Industry

Integrity-Based, Customer-Oriented

Focus on high-quality cast steel, create value for customers

The company owns more than 100 sets of sophisticated equipment including large electric arc furnaces, CNC natural gas heat treatment furnaces, large vertical lathes, hoisting equipment, hobbing machines, a trolley-type shot blast machine, and so so.

The company is equipped with auxiliary facilities: gas stations, oxygen stations, carbon dioxide stations, air compression stations, etc. It adapted the sodium silicate sand molding process, and the CAE casting simulation software, to shorten the trial-produce period, and improve the quality of products.

The company owns the GS-1000 vacuum direct reading spectrometer, carbon-sulfur analytical instrument, microcomputer three-speed analytical instrument, mechanical properties testing machine, low-temperature impact testing machine, UT, MT inspection equipment, etc.

CHAENG strives to be perfect in every link, make every casting perfect, and win the trust of every customer.

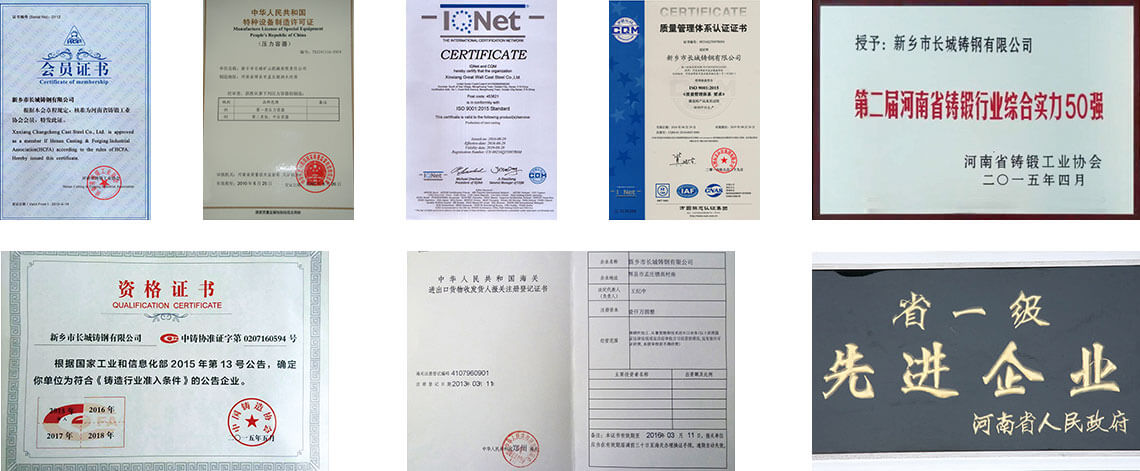

The company is one of the announced enterprises (first batch) in "Access Condition for Foundry Industry" approved by the Ministry of Industry and Information Technology, has passed ISO quality, environment, occupational health, and safety system certification, and won the honorary title of One Thousand of Key Enterprises in China Foundry Industry.

The company attaches great importance to environmental protection work, and always adheres to the concept of "green development, ecological casting". At present, a total of 20 million yuan has been invested in the in-depth transformation of each production process. The company will continue to strengthen environmental protection governance to achieve both environmental protection and economic benefits.