specification

Weight1-300 Tons

MaterialSteel ZG55, ZG42CrMo, etc.

ApplicationRotary kiln, rotary dryer, rotary cooler, etc.

CustomizableYes, according to customer's drawings

The rotary kiln support roller device bears the weight of the entire rotating part and plays a directional effect on the cylinder, and enables the rotary kiln cylinder and riding ring to rotate smoothly. So it requires that the support roller has high endurance quality.

CHAENG, as a leading manufacturer of large steel castings with 15 years of experience, can provide custom service for different sizes of rotary drum supporting rollers.

Weight1-300 Tons

MaterialSteel ZG55, ZG42CrMo, etc.

ApplicationRotary kiln, rotary dryer, rotary cooler, etc.

CustomizableYes, according to customer's drawings

1. CAE software digital simulation technology is used to predict the casting quality and optimize the casting process.

2. CHAENG adopts normalizing and tempering processes, so that the surface hardness of the support roller is higher than 200HB, with good high temperature resistance and low friction resistance.

3. CHAENG has German OBLF direct reading spectrometers, carbon and sulfur high-speed analyzers, and three-element high-speed analyzers, which can test and analyze various raw materials to ensure that the chemical composition meets the standards.

4. The support roller device adopts rolling bearing wheel set, which has a simple structure and is easy to maintain.

5. We ensure quality through strict inspection system: chemical composition, mechanical property, dimensional check, ultrasonic testing (UT), magnetic particle testing (MT), penetrant test (PT), and X-ray inspection.

Simulation & analysis

Wood pattern

Sand mould

Smelting

Molten steel test

Pouring

Sand cleaning

Heat treatment

Finishing

Machining

Non-destructive testing

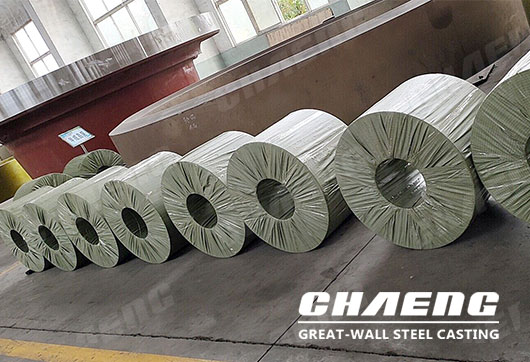

Packaging & delivery

CHAENG rotary kiln support rollers are used in many cement production lines in China, for example: 5000TPD cement rotary kiln of Henan Meng Electric Cement Factory.

CHAENG kiln support rollers were exported to South Africa.

A Philippines company purchased ten pieces of rotary kiln support rollers from CHAENG.