Process of large steel castings

16 Aug 2022 UTC+8Views:

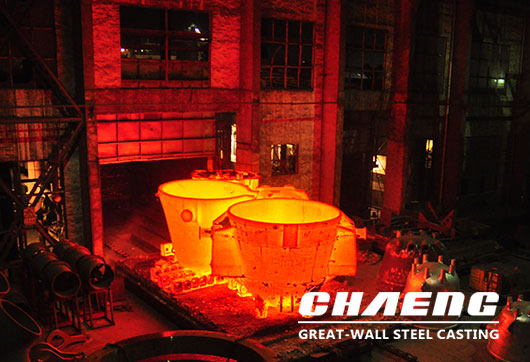

The casting process is to melt the metal and pour it into a mold to cast various steel castings.

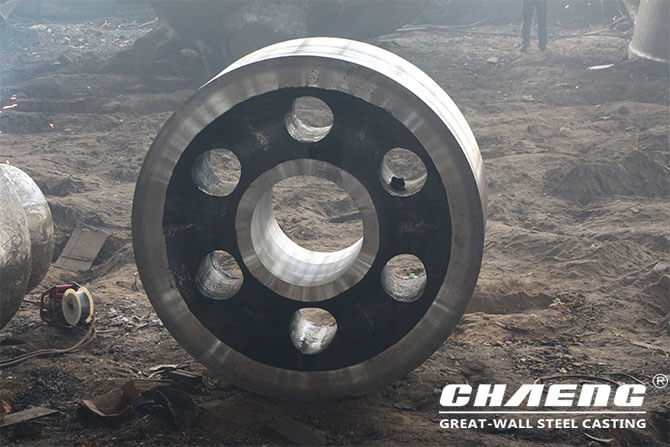

Many large steel casting manufacturers mainly use the sand casting process, in which the mold used is a wooden mold, which can be used repeatedly and is suitable for large-scale steel castings , with strong production flexibility and relatively light uses. Generally, the weight of castings produced by large casting factories is from 1 ton, and the steel used is ordinary carbon steel or low alloy steel castings. The castings produced by some manufacturers can be small, depending on the strength and scale of the manufacturer; in sand casting, the model made by the wooden mold has the same shape as the casting. When the molten steel solidifies, the sand mold will be removed by the manufacturer, and the wooden mold and sand can be removed. Reusable, so sand casting is cost-effective.

There are also processes of rapid prototyping, centrifugal casting, and extrusion of semi-solid metal blanks into molds or dies, which are generally suitable for small steel castings and can be mass-produced.

Using sand casting process, CHAENG can process large steel castings with a single weight of 1 ton to 150 tons, such as: rotary kiln tyres and supporting rollers, gear rings, slag pots, etc. The flaw detection standard adopts the international secondary flaw detection, and the products are sold at home and abroad. Welcome to consult anytime!