CHAENG support roller for kiln, production details determine success

26 Mar 2019 UTC+8Views:

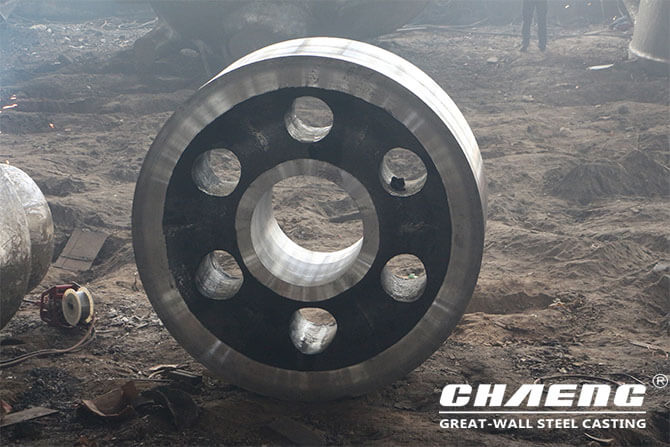

The support roller for kiln is an important part of the rotary kiln to bear the full weight of the rotating part (including the cylinder, material, nutrient plate, tyre, girth gear, etc.), and to position the cylinder in the radial direction. Because the rotary kiln support roller has the characteristics of large bearing load, poor working environment, continuous operation, and time-consuming maintenance of maintenance, every detail of the processing of the supporting roller needs the attention of the roller processing factory.

CAHENG, as an experienced rotary kiln support roller manufacturer, pays great attentions in every production step of the support roller.

1. CHAENG uses ZG55, ZG42CrMo materials with excellent quality

The support roller device consists of a pair of rollers, four pairs of bearings and a large base. CHAENG uses high quality ZG55, ZG42CrMo materials to make support roller for kiln, to guarantee the quality.

2. CHAENG adopts normalizing and tempering process. The hardness of the support roller is higher than 200HB.

CHAENG support roller for kiln adopts the rolling bearing-roller set, which has the characteristics of simple structure and convenient maintenance, and adopts the process of normalizing and tempering. The hardness of the support roller is higher than 200HB, which greatly guarantees the quality of the support roller for kiln.

3.CHAENG optimizes the casting process by computer software

Before casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize the product quality.