Slag pot manufacturer for steel mills - CHAENG

27 Jun 2018 UTC+8Views:

Slag pot is important container holding high temperature liquid steel slag in the process of steel making. CHAENG, as a experienced slag pot manufacture and exporter, makes great innovations in casting process of slag pot to gives the CHAENG slag pot advantages of short production cycle, long service life and strong deformation resistance.

CHAENG slag pot spec:

Material: DIN 17182 GS-16Mn5 1.1131

Weight: 1-150tons

Size: customized according to customers’ drawings

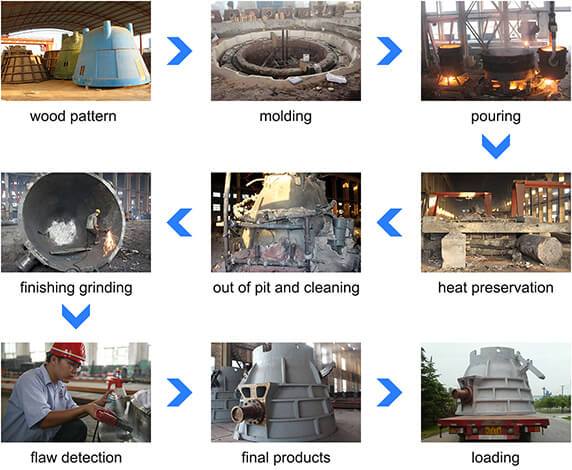

CHAENG slag pot manufacturing process:

Except the supply of the forgings for trunnions and the engineering of the pattern, all further operations are carried-out at the in-house foundry plant.

• Moulding

Sand moulding.

• Trunnions

The trunnions - when any - are preferably cast-in: they are as a rule manufactured from the steel material S355 J2G3 to DIN EN 10250-2.

• Melting

The melting is carried out in the oxygen steel plant; the ladle capacity allows a continuous bottom pouring process the speed of which is permanently controlled. The metal analysis is checked by using a computer linked spectrograph.

• Heat treatment

- Heating to a temperature above AR3, austenitising at about 915°C and controlled cooling in furnace

- Intermediate holding at 600°C - 630°C and completion of cooling in furnace down to 300°C

• Fettling and dressing

The inner surface is processed fit-for-purpose so that the surface discontinuities - which might cause some sticking of the slag - are extensively removed. Additionally, the castings are descaled by shotblasting and the outside is additionally coated for transportation.

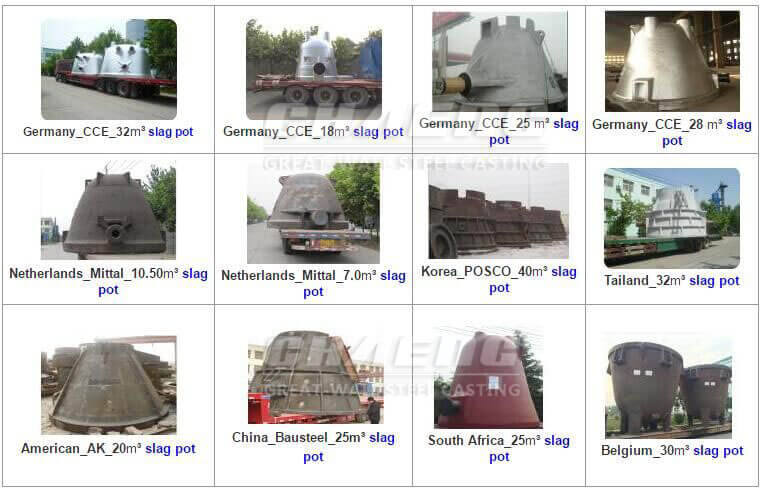

CHAENG slag pot cases:

Why do so many customers choose CHAENG slag pots:

1. Durable: CHAENG slag pot engineers adopt suitable material, customize and optimize the casting technology according to actual operating conditions. So CHAENG slag pots have: excellent high temperature mechanical properties, good thermal cracking resistance, stable manufacturing process and so on.

2. Longer service life: Up to 6000 times of usage frequency. First maintenance can be done 2~3 months later than similar products from other manufacturers.

3. Mature casting processes, rich experienced manufacturer: CHAENG, as a rich experienced manufacturer, has mature casting process and technical teams. CHAENG performs digital simulation of casting process by means of CAE before pouring, to achieve the optimization of slag pot casting process.

4. Level 2 of flaw detection: Ultrasonic and magnetic particle flaw detection level can reach the second level of standards.

5. Smooth side wall: Smooth inner wall of slag pot, to avoid adhering slag during operation.

6. Good appearance: CHAENG is quite skillful at shot blasting and sand blasting to ensure the good appearance of slag pot / slag ladle and improve paint adhesion.

Contact CHAENG for slag pots:

E-mail: casting@chaeng.co

Tel.:86-371-55019878

Skype ID: greatwall1958