FAQ: what is the price of the 2m girth gear of CHAENG?

22 Jun 2018 UTC+8Views:

When receiving users, we always face the questions of users like “how much is a 2m girth gear” and “how much is the current cost per ton of cast steel”? On the one hand, users can measure the quality of a large girth gear based on the price, and on the other hand, consider the appropriate large girth gear manufacturer in combination with its own budget.

However, about the price question of girth gear. It can’t be answered simply based on diameter or weight, because girth gear is large mechanical part which should be produced well matching with mill and kiln equipment. CHAENG manufactures girth gear and calculate price according to users’ drawings and specification requirements. So when you send the inquiry, please kindly offer us clear drawings and tell us your detail requirements on payment terms and quantities.

As a professional large girth gear manufacturer in China, CHAENG advises users to consider comprehensively when selecting a suitable large girth gear for their own production

Detail processing is crucial to the quality of the girth gear.

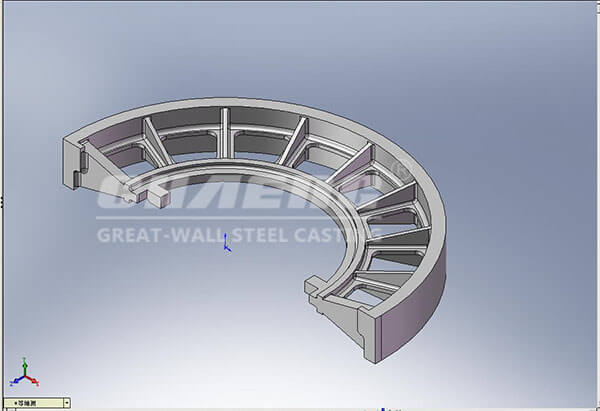

Users who are familiar with the production of steel casting girth gear all know that there are many uncontrollable factors in the casting process and these uncontrollable factors often lead to casting defects. Therefore, CHAENG uses computer simulation technology to visualize the entire girth gear casting process before casting each large girth gear to avoid the occurrence of casting defects in girth gears.

CHAENG is strictly controlled in every aspect of production, and supervise the product details. It insists on achieving zero defects before shipment. This ensures the high quality of the product and allows users to use it with confidence.

Fully meet user's demand for large girth gear

CHAENG has been committed to providing users with high-quality and complete large steel casting processing solutions, from the selection of girth gear materials, casting process, mechanical properties, flaw detection requirements, to delivery of finished products. The quality of girth gear is upgraded in all directions.