10m³ and larger slag pot manufacture

19 Jun 2018 UTC+8Views:

Slag pots are important equipment for steelmaking in the metallurgical industry, and their quality directly affects production.

Large-scale steel mills generally purchase large slag pots of more than 10m³, and their size is too large to control in production. Because slag pots always need to be in contact with high temperature smelting slag, it is prone to thermal fatigue. Therefore, cracks, shrinkage holes, porosity, pores, sand hole, slag inclusions, cold gaps, and other casting defects that affect quality are not allowed in the casting process.

Comprehensively analyzing the structure and process of large steel casting slag pots and combining the past 10 years of casting process experience, CHAENG has effectively prevented the occurrence of cracks and shrinkage, and produced qualified casting slag pots.

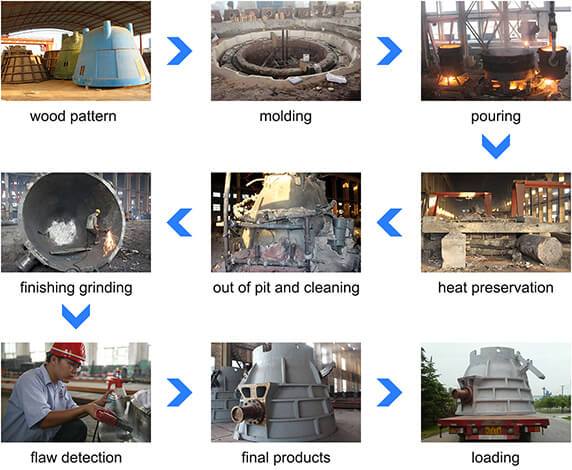

How CHAENG to manufacture high-quality large slag pots?

1. Introduce top-level production equipment, commit to intelligent, large-scale production of steel castings, and firmly prevent defective products from being delivered.

2. CHAENG follows the GB level 2 inspection standard, performs 360° non-destructive testing system, UT, MT inspection equipment, OBLF GS-1000 direct reading spectrometer, carbon-sulfur analyzer, three-element analyzer, mechanical performance test Machine, impact test cryogenic tank, impact testing machine, etc. The purpose is to achieve a precise ratio of the chemical composition of the cast steel to ensure the quality of steel castings.