How to solve the bad lubrication of rotary kiln support roller bearing bush in summer

06 Jun 2018 UTC+8Views:

This article take the situation which a large cement factory encountered as example to discuss how to solve the lubrication problems of kiln support roller in summer.

In a rotary kiln with a multi-cylinder cooler of the factory, the lubrication of the first-gear support roller bearing bushing is poor, and the lubrication condition is worse in the hot summer season. Later, the reasons for the poor lubrication of the bearing bushing were mainly as follows:

1. The amount of oil brought to the sump by the oil spoon is too small;

2. Due to the large load of the first-gear support roller and high ambient temperature, No. 24 saturated cylinder oil used in the plant can not meet the lubrication requirements;

3. The radiating temperature of the kiln shell and the multi-cylinder cooler on the bearing housing is high.

The factory has increased the number of oil spoons, used lubricants with a high viscosity index in the summer, and added thermal insulation water jackets, so as to improve the lubrication of the support roller bearing bush. The specific practices are described as follows:

(1) Increased the number of oil spoons. The original roller lubrication device was designed with 6 oil scoops. In order to increase the oil volume of the lubricant, the oil scoop was increased to 12. That is, drilling and tapping were made between the original oil spoons, and 6 oil spoons were added evenly.

(2) Use a lubricant with a high viscosity index. In the summer, the No. 65 saturated cylinder oil was used for the first-gear supporting rollers, if the roller journal oil film is poor, the No. 9 molybdenum disulfide grease and the No. 65 saturated cylinder oil were generally used, and the uniform mixture of them was more effective.

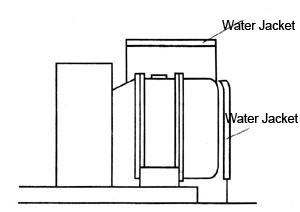

(3) Add heat insulation circulating water jackets outside the bearing seat. The rotary kiln originally equipped rubber asbestos heat insulation board outside the supporting roller bearing, and the practice proved that its heat insulation effect was poor. So in the position where the bearing was closed to the kiln cylinder body and the cooler cylinder elbow, heat insulation water jackets were installed and played a good thermal insulation effect, see figure.

Diagram of heat insulation water jackets

Through the above measures, the lubrication of the support roller and the operation rate of the equipment were improved.