Three reasons for the vibration of the girth gear of rotary kiln

10 May 2018 UTC+8Views:

The girth gear of rotary kiln is an important component, on which major obstacle that may occur during operation is vibration. Therefore, it is an important part of the rotary kiln repair work to clarify the causes of the girth gear vibration and to take corresponding treatment methods.

1. Caused by the connector wearing. The girth gear is connected to the kiln body through the spring plate shaft pin. The girth gear itself is manufactured in segments and integrated with the counter screw. When pins and counter screws are worn out, the girth gear are loosened. The sinking of partial girth gear can also cause the tooth tip clearance to become smaller and cause vibration.

2. Caused by kiln bending. This is obvious. Vibration caused by the kiln bending mainly occurs in the cold test run, and the hand-transmitted vibration range of the kiln was synchronous with the kiln bending direction. The temperature can be increased to open the kiln and the internal vibration will be eliminated in a short time.

3. Caused by tooth thickness wear. This is also considered from the fact that the tooth tip clearance becomes smaller. Obviously, after the tooth is worn out, it creates a "gross" backlash. Because this headspace is caused by wear and has a running-in nature, so the distance between the centers of the two gears is slightly changed, and there will result in vibration.

It is difficult to explain the vibration caused by tooth-thickness wear by measuring the head-gap normally. The head-end gap may be large at this time, but the vibration does exist and the hand feels continuous and rhythmic vibration. The method of judgment is to reverse the kiln. After the reversal, if the vibration is eliminated immediately, it can be judged. When processing, just move the pinion bearings a little outward to increase the center distance.

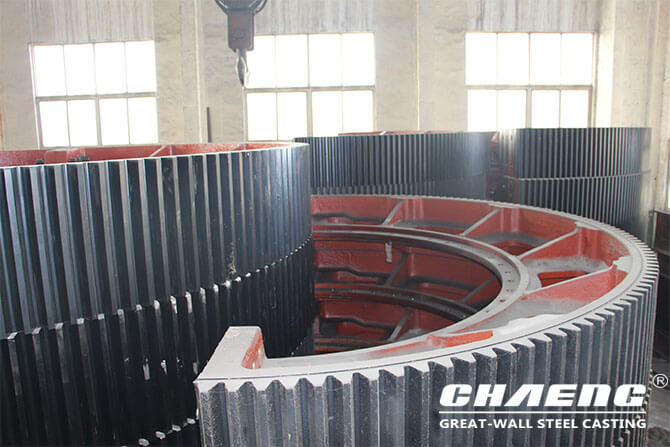

With continuous efforts on process optimization on the basis of rich manufacturing experience and advanced equipment, CHAENG is able to offer high quality cast steel girth gears according to users' drawings and requirements.

1. Special Heat Treatment Technology

CHAENG adopts special heat treatment technology to optimize structure, improve the hardness and enhance the impact-resistance of girth gear.

2. Long Service Life

CHAENG uses high-strength steel materials to produce girth gear, and optimizes the structure of girth gear according the drive characteristics of rotary kiln and ball mill, to ensure the long-term stability of the girth gear.

3. Factory Price, Custom & Quick Delivery

CHAENG is large steel casting company with strong production capability, we can provide girth gear within short period.

Welcome to consult us for girth gears!

E-mail: casting@chaeng.co

Tel.:86-371-55019878

Skype ID: greatwall1958