Repair and replacement standards for main wear parts of cement rotary kiln

22 Jul 2020 UTC+8Views:

During the operation of the cement rotary kiln, the wear of parts and the reduction of equipment accuracy will affect its operation rate, and it must be repaired or replaced. Based on years of experience in the production of large-scale steel castings, CHAENG has summarized the repair and replacement standards for the main wearable parts of cement rotary kilns such as girth gears, riding rings, supporting rollers, and thrust rollers for reference.

Girth gear

The girth gear is one of the key components in the rotary kiln transmission device, which is prone to deform and break. When the tooth thickness of the girth gear is worn by 30%, or the gear flange has irreversible damage, it needs to be repaired and replaced.

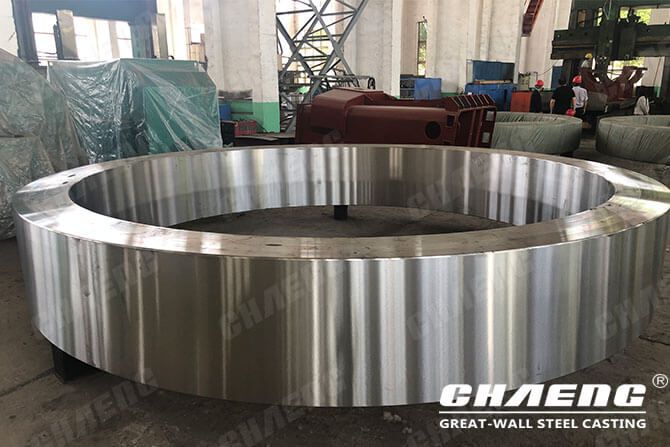

Riding ring

The riding ring is one of the main components of the rotary kiln equipment. Its function is to transfer all the weight of the kiln body to the supporting roller and to enable the kiln to rotate smoothly on the supporting roller. When the section of the riding ring is worn out by 20%, or the surface is worn into a tapered, polygonal shape, or partial penetration cracks appear, it needs to be repaired and replaced.

Support roller

When the diameter of the journal of the supporting roller and the thrust roller is reduced by 20%, or the thickness of the supporting roller rim is ground by 25%, or the rim is ground into a conical or other abnormal shapes, or the rim has a through crack, repair and replacement are required. When replacing the supporting roller and the thrust roller, the corresponding lining must be scraped or replaced.